Designed for Performance, Built for a Carbron-Free Future

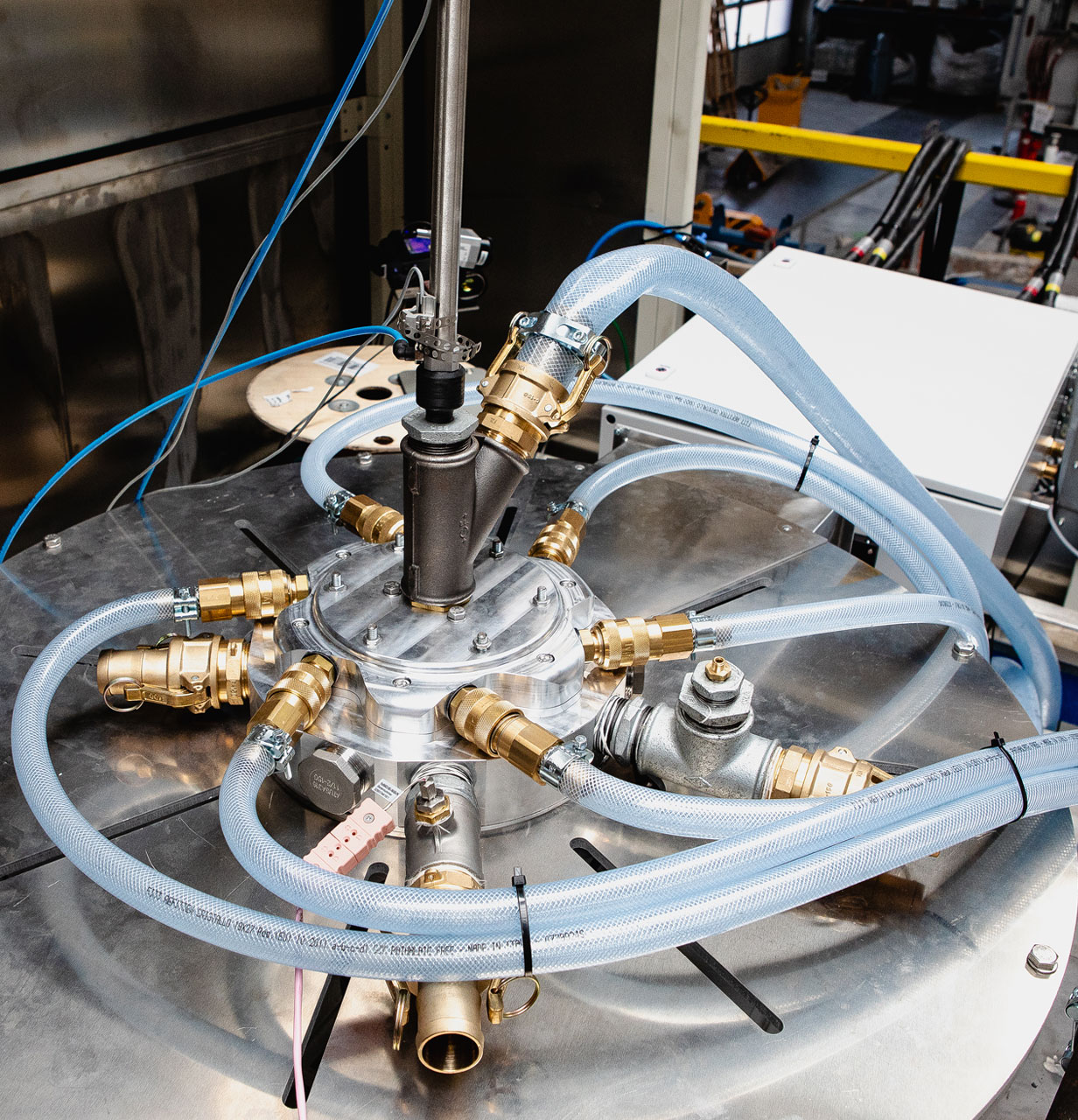

Discover Our Plasma Burner

Our inductively coupled plasma burner with power targeted up to 1 MW consists of a high-frequency plasma torch, corresponding power electronics, and a control unit. It generates stable plasma with precisely adjustable heat input and is scalable for various furnace sizes. We provide a complete burner solution, including process simulation, customization for specific operating conditions, and integration into both new and existing facilities.

- CO2-neutral > 10 t furnace capacity secondary aluminum

- Installation in existing gas-fired facilities possible

- Low primary energy requirement

- Lower maintenance cycles and overall operating costs

Why Plasma for Aluminum?

Aluminum is infinitely recyclable — but to unlock its full environmental potential, the melting process must also be decarbonized. At TPS, we are developing plasma burner systems for furnaces (with outputs 1 MW to exceeding 10 MW) specifically for small and large-scale aluminum melting applications.

Our technology offers a groundbreaking alternative to natural gas or hydrogen combustion, contributing directly to the decarbonization of the aluminum sector.

High Torch Temperatures

Compared to conventional combustion with natural gas or hydrogen, our plasma burners achieve significantly higher flame temperatures. This results in a greater temperature differential between the burner and the material, improving the thermal efficiency and reducing flue gas losses.

Reduced Oxidation & Meal Loss

Operating in a controlled, low-oxygen atmosphere, the plasma burner minimizes aluminum oxidation, which translates to less dross, lower metal losses, and higher material efficiency. Less aluminum is needed to achieve the same output.

Lower Hydrogen Inclusions

By eliminating water vapor and hydrogen-rich combustion atmospheres, our plasma technology reduces hydrogen inclusions in the melt. Depending on the alloy, this can minimize or eliminate the need for degassing, while improving overall product quality.

Inert Furnace Atmospheres

Unlike gas or hydrogen combustion, the plasma burner allows for fully inert atmospheres, supporting pyrolysis processes, reducing oxidation on product surfaces, and minimizing wear on refractory materials.

Plasma Technology for a Wide Range of High-Temperature Industries

Expanding Horizons

TPS is continuously advancing its solutions to meet the decarbonization needs of sectors like cement, steel, chemical, copper, glass, and ceramics — enabling CO₂-free heating across industrial applications.