Technology

A New Era in Industrial Heating

At TPS, we are redefining how aluminum is melted — with zero CO2-emissions and maximum compatibility with existing systems. Our plasma burner technology is built to make the shift to sustainable production seamless and future-proof.

Technical Highlights

Our plasma burner uses induction to create plasma instead of relying on fossil fuels like natural gas or fuel oil. This method enables carbon-neutral operation when powered with green electricity — offering a truly sustainable alternative to conventional gas burners.

Retrofit-Ready

The system is designed for easy integration into existing gas-fired installations. No complete overhaul needed — our burners can replace traditional gas burners directly.

Protected Components

Critical components are kept away from direct contact with plasma. This reduces the maintenance ompared to other plasma technologies.

CO2-free Aluminum Melting

By eliminating fossil fuel combustion and using green power, TPS enables carbon-neutral aluminum melting.

Less Dross Formation

As oxygen is eliminated from the furnace, dross generation is significantly reduced — improving material yield and product quality.

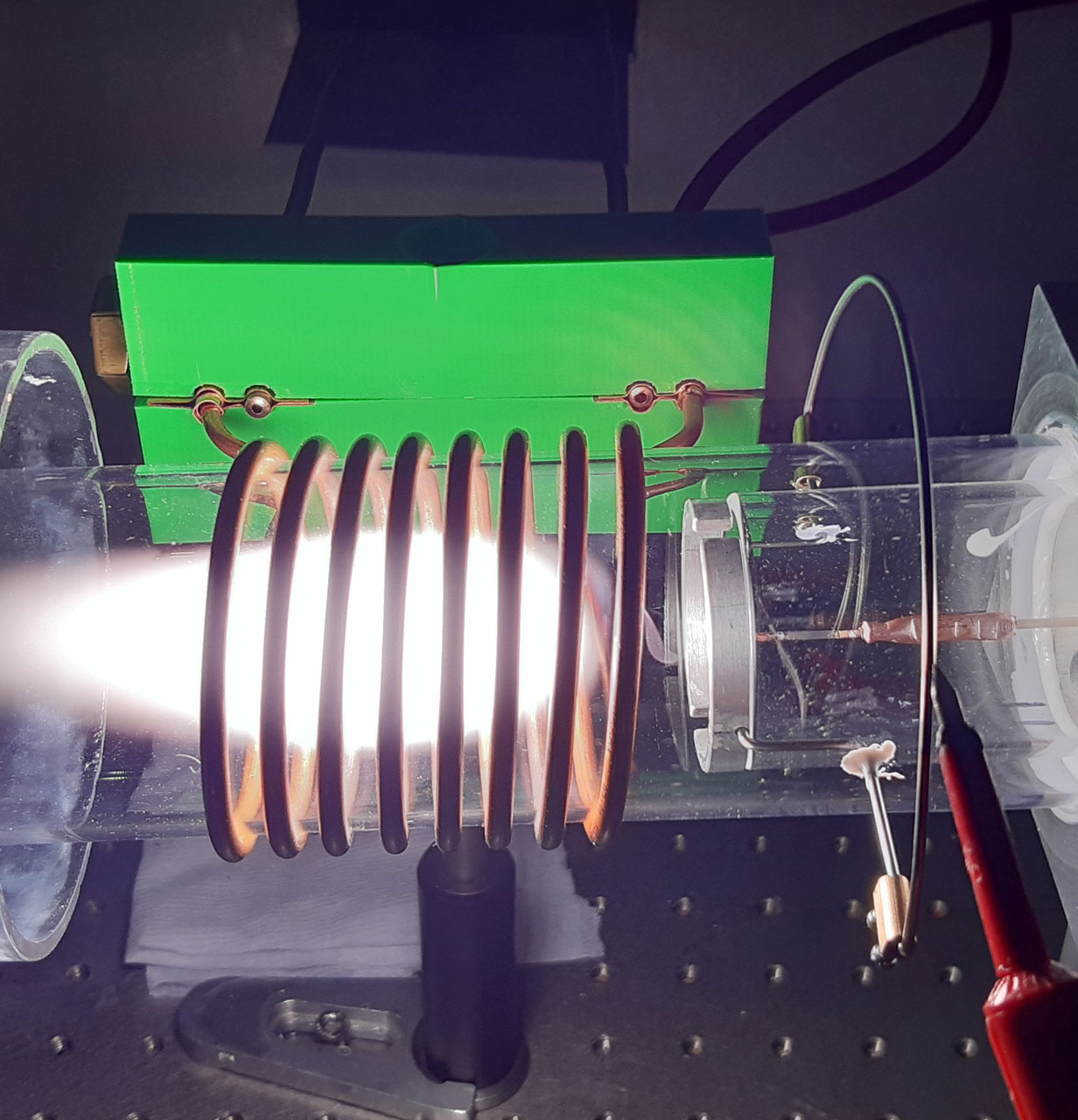

Inductively Coupled Plasma

How Our Plasma Burner Works

Our plasma burner uses induction to create plasma instead of relying on fossil fuels like natural gas or fuel oil. This method enables carbon-neutral operation when powered with green electricity — offering a truly sustainable alternative to conventional gas burners.

- A by radio frequency operated inductive coil introduces electromagnetic energy into a ceramic tube

- A gas flow is introduced through that tube

- An ignition device ignites the plasma

- In the plasma state, the electromagnetic energy is transferred to the flow. A stable flow of plasma is produced

- The plasma forms a "flare", that will transfer the available energy to the product

- For a lower media consumption during the process the "exhaust gas" can be recycled back into the burner and reused

Driving Green Technologies

Built for a Cleaner Future

By combining cutting-edge technology with real-world practicality, TPS brings industries one step closer to CO₂-free production — without compromising on performance or flexibility.